Electrolytic tin plate: also known as tinplate, is a product that is plated with a layer of tin on the surface of a low-carbon thin steel plate through an electrolytic process. It has the advantages of both the strength of steel and the corrosion resistance of tin. ETP (Electrolytic Tin Plate) is its common type.

TFS: Tin Free Steel, a sheet formed on a steel substrate using non-tin coating technology, has good corrosion resistance and processing performance, and is often used as a substitute for electrolytic tin plate.

Functions of tin coating:

1. Anti-corrosion: Tin has good chemical stability and can form a protective film on the surface of the sheet, effectively blocking air, moisture and other corrosive substances from contacting the steel sheet, and extending the service life of the sheet. For example, in food packaging, it can prevent the contents from being oxidized and deteriorated.

2. Aesthetics: The surface of the tin coating is smooth and bright, which can improve the appearance quality of the sheet, make the product more attractive, and meet the appearance requirements of different application scenarios.

3. Solderability: Tin has good solderability, which is convenient for welding the sheet during processing, and is conducive to making products of various shapes, such as welding into food cans, electronic component housings, etc.

Application advantages:

1. Food packaging field: It can ensure that food is not corroded during the shelf life and maintains its quality. The tin coating is non-toxic and meets food hygiene standards.

3. Electronic field: Good solderability and corrosion resistance can meet the packaging requirements of electronic components and circuit board manufacturing requirements, and ensure the performance and reliability of electronic equipment.

3. Daily necessities field: Such as used in the manufacture of various metal containers, decorations, etc., which are both beautiful and durable, and improve product texture and service life.

Electrolytic Tin Plate Paramenters

Prime quality tin plate sheet electrolytic tinplate transparent

coated for tin can making

| PRODUCT |

Prime tinplate |

| STANDARD |

BS EN 10202, DIN EN 10203, GB/T2520 , JIS G3303 |

| MATERIAL |

MR SPCC |

| Grade |

Prime |

| Annealing |

BA,CA |

| THICKNESS |

0.14-0.45mm |

| WIDTH |

600-1050mm |

| TEMPER |

T2, T2.5, T3, T3.5, T4,T5 ,DR7,DR7M,DR8 |

| COATING: |

2.8g/2.8g, 5.6g/5.6g, 2.8/5.6,2.0/2.0 gr/m² or according to customer's requirement |

| FINISHS: . |

Bright,Silver,Stone, Matte |

|

PACKINGS:

|

export packing. Or according to customer's requirements. |

| MOQ |

25 tons |

| DELIVERY |

15-30 days after payment |

Matt Surface Tinplate Welding Tin Plate Sheet

| Product |

Tinplate Sheet |

| Standard |

ASTM A623, EN 10203, GB2520-2000,JISG3303-2002 and DINEN10202-2001 |

| Material |

MR SPCC |

| Thickness |

0.14mm- 0.40mm (tolerance -/+0.01 mm) |

| Width |

600~1050mm (Tolerance: 0~3mm) or as per customers' requires |

| Cutting Length |

600~1050mm (Tolerance: 0~3mm) or as coils |

| Annealing |

BA & CA |

| Temper |

T1 T2 T3 T4 T5 DR8 DR9 TH550 TH580 TH620 TH660 |

| Tin Coating |

1.1/1.1 2.0/2.0 2.8/2.8 2.8/5.6 5.6/5.6 8.4/8.4 11.2/11.2 g/㎡ |

| Surface finish |

Bright, Stone, Silver, Matt, Rough stone. |

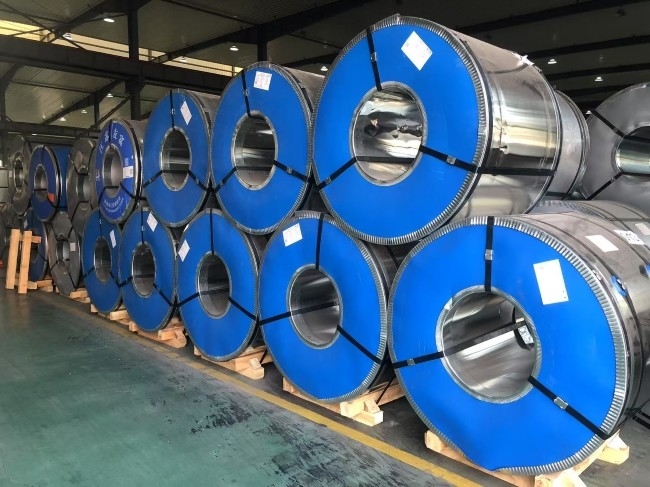

| Coil Diameter |

ID 420/ 508/610mm, OD from 1,000 to 1,250m |

| Coil Weight |

3~10 MT |

| Package |

Seaworthy Standard with wooden pallet, corner protected. by sheet or coils according customer's requires. |

| Applications |

Metal package usage like paint, chemical can,aerosol can and different food can production, Also battery,electric cable and other industries |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!