Printed Coated Tin Free Steel TFS Tinplate Sheet For Chemical Can Packaging ETP TFS

ETP TFS is a tin-free steel coil used for chemical tank packaging. Its full name is Electrolytic Tin Free Steel. It is based on cold-rolled low-carbon steel plate. Through the electrolytic process, a very thin layer of chromium or chromium oxide coating is formed on the surface, replacing the traditional tin plating layer. It is often used in the field of chemical tank packaging that has certain requirements for corrosion resistance and printability.

Features

1. Good corrosion resistance: The chromium or chromium oxide coating on the surface can effectively block the contact between chemical substances and the steel substrate, resist the erosion of various chemical substances, and ensure that chemical tanks will not be damaged or leaked due to corrosion during storage and transportation.

2. Excellent printability: The coating surface is flat and smooth, which can provide a good foundation for printing. The ink has strong adhesion on its surface, and the printed pattern is clear, firm, and colorful, which can meet the needs of chemical product packaging in appearance design and identification.

3. High strength and toughness: With low-carbon steel as the substrate, it inherits the high strength and good toughness of steel, can withstand a certain degree of collision, extrusion and other external forces, is not easy to deform or break, and ensures the stability of chemical tanks in various environments.

4. Environmental protection: Compared with tin-plated steel sheets, Wuxi steel coils do not require the use of tin resources during production, reducing dependence on limited metal resources. The chromium coating is more in line with environmental protection requirements to a certain extent, reducing potential harm to the environment.

5. Cost advantage: Since relatively expensive tin is not used, production costs are reduced. While ensuring packaging performance, it can save packaging costs for chemical product manufacturers and improve the market competitiveness of products.

Different Features between TFS and ETP

Appearance

Even when the same surface finish as ETP is applied to the substrate steel sheet, it provides the unique surface

luster characteristic of metallic chromium.

Corrosion resistance

As it has excellent corrosion resistance after painting, it is generally used with both surfaces painted. It can also be

used with the internal surface unpainted, depending on the contents.

Solderability

TFS is not compatible with soldering.

Weldability

Although TFS can be welded when the metallic coating layers are removed, its weldability is inferior to ETP.

Coating weights

Unlike the multiplicity of coating weights with tin, only one standardized chromium-coated product is manufactured.

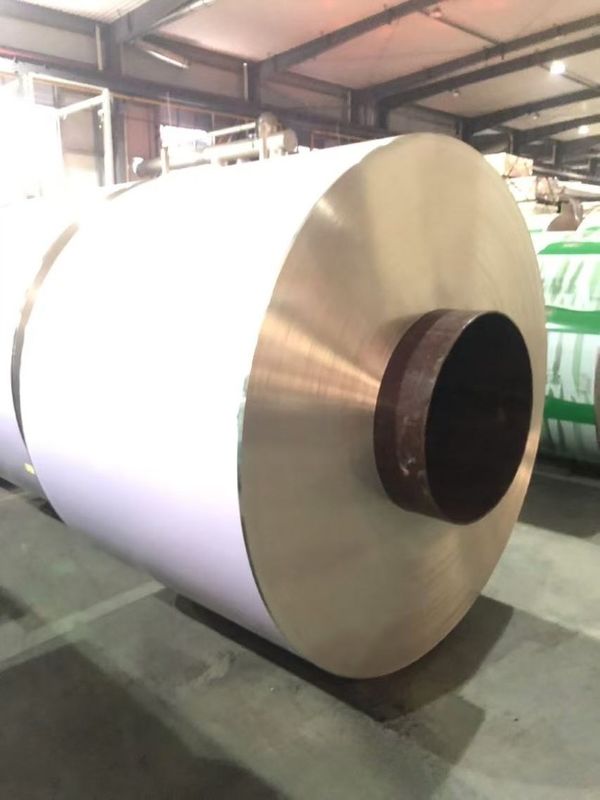

Workshop Show

Production Process

PARTNER

HONOR CERTIFICATE

Packing

Offers coils and sheets, coil packed in a vertical form or a horizontal.

A label that indicates the manufacturing history is affixed to the outside of the packaging.

In addition, a service card is contained inside.

With regard to types of packing and markings, please consult us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!